Search:

Safety mechanisms without derived actions

Explanation:

A search will be performed for (linked) error- detections & responses which have no actions (detection or preventive) derived for customer operation

Example:

Abbreviations

- ASIL = Automotive safety integrity level

- BF = Base failure of a base function

- BFn = Base function of a base structure element

- BSE = Base structure element

- Cl Prc = Classification for process characteristic

- Cl Prd = Classification for product characteristic

- Cl Req = Classification for requirement

- CM = Control method

- DA = Detection action

- DC = Diagnostic coverage

- DSCF = Dangerous safety critical failure

- Er Det = Error detection

- Er Resp = Error response

- F = Failure

- FIT = Failure in time

- Fn = Function

- FSM = Functional safety management

- IE = Inspection equipment

- LF = Latent fault

- LFM = Latent fault metric

- OC = Operating condition

- PA = Preventive action

- PE = Process element

- PFH = Probability of failure per Hour

- PMHF = Probabilistic metric for random hardware failures

- PrcC = Process characteristic

- PrdC = Product characteristic

- QM = Quality method

- QR = Quality rule

- Req = Requirement

- RMR = Risk Matrix Ranking

- RP = Reaction plan

- SE = Structure element

- SE ErDet = Structure element for error detections

- SE ErResp = Structure element for error responses

- SFF = Safe failure fraction

- SG = Safety Goal

- SIL = Safety integrity level

- SM = Organisational-SE for “safety mechanisms”

- SPF = Single point fault

- SPFM = Single point fault metric

- TF = Top failure of a top function

- TFn = Top function at root element

- TS = Test sample

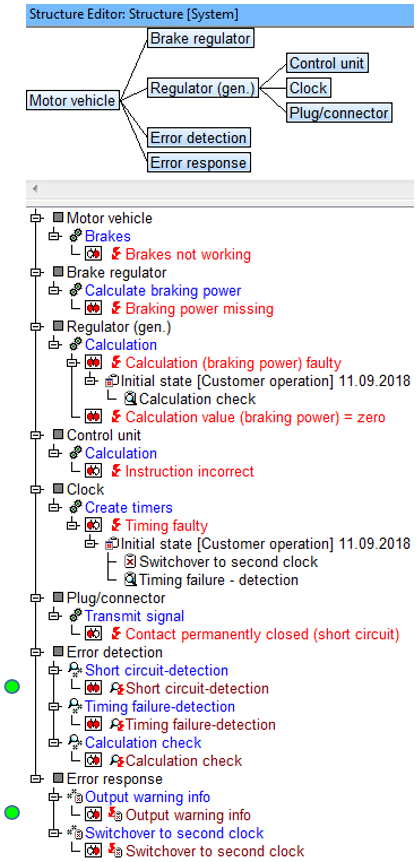

- The above structure shows a compressed extract from the braking system of a vehicle. For the sake of clarity, the error detections and error responses are in two separate structure elements.

- This Quality Rule identifies any error detections or error responses, which have not yet been turned into preventive- and detection actions from the failure net, via the mechanism “Derive actions for customer operation”, and have been anchored as actions at immediate causes.

- By focusing on the error detections in the failure net, with the display option “Actions” active, it is possible to see which error- detections and responses have not yet been converted.

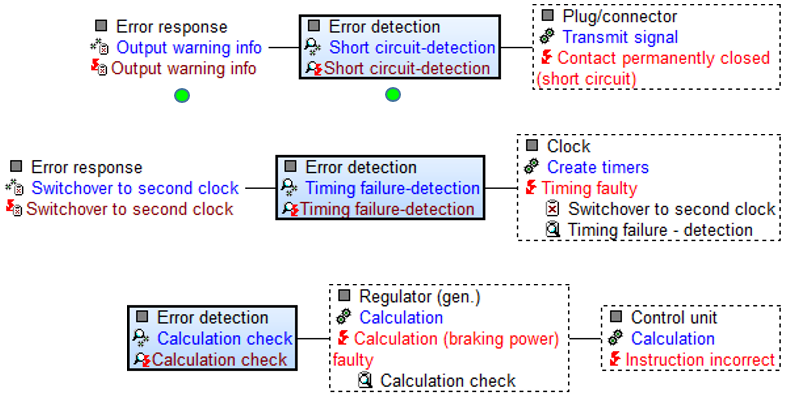

- How the error detections are linked in the failure net can be seen here:

Of all the error detections in this example, two have been made into actions for customer operation and anchored at immediate causes of failures belonging to error detections. An error response associated with an error detection is automatically turned into an action for customer operation if this option is applied to the error detection.

Search result: ![]()

Hits here are: “Short circuit-detection“and “Output warning info“.