Search:

Characteristics (Control Plan) without inspection equipment

Explanation:

Searches for (Control Plan relevant) product and process characteristics without inspection equipment.

Example:

Abbreviations

- ASIL = Automotive safety integrity level

- BF = Base failure of a base function

- BFn = Base function of a base structure element

- BSE = Base structure element

- Cl Prc = Classification for process characteristic

- Cl Prd = Classification for product characteristic

- Cl Req = Classification for requirement

- CM = Control method

- DA = Detection action

- DC = Diagnostic coverage

- DSCF = Dangerous safety critical failure

- Er Det = Error detection

- Er Resp = Error response

- F = Failure

- FIT = Failure in time

- Fn = Function

- FSM = Functional safety management

- IE = Inspection equipment

- LF = Latent fault

- LFM = Latent fault metric

- OC = Operating condition

- PA = Preventive action

- PE = Process element

- PFH = Probability of failure per Hour

- PMHF = Probabilistic metric for random hardware failures

- PrcC = Process characteristic

- PrdC = Product characteristic

- QM = Quality method

- QR = Quality rule

- Req = Requirement

- RMR = Risk Matrix Ranking

- RP = Reaction plan

- SE = Structure element

- SE ErDet = Structure element for error detections

- SE ErResp = Structure element for error responses

- SFF = Safe failure fraction

- SG = Safety Goal

- SIL = Safety integrity level

- SM = Organisational-SE for “safety mechanisms”

- SPF = Single point fault

- SPFM = Single point fault metric

- TF = Top failure of a top function

- TFn = Top function at root element

- TS = Test sample

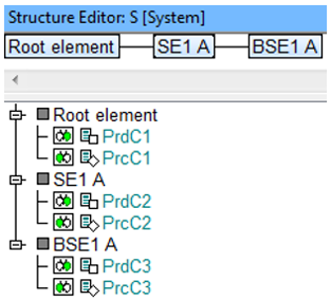

- The above structure contains three structure elements, each of which have both one product characteristic

(

) and one process characteristic (

) and one process characteristic ( ) assigned to them. The characteristics of each structure

element are linked to each other within a function net and can be recognized with the hot-click icons

) assigned to them. The characteristics of each structure

element are linked to each other within a function net and can be recognized with the hot-click icons  and

and  .

.

- The nets show how the characteristics are linked to each other as follows:

![]()

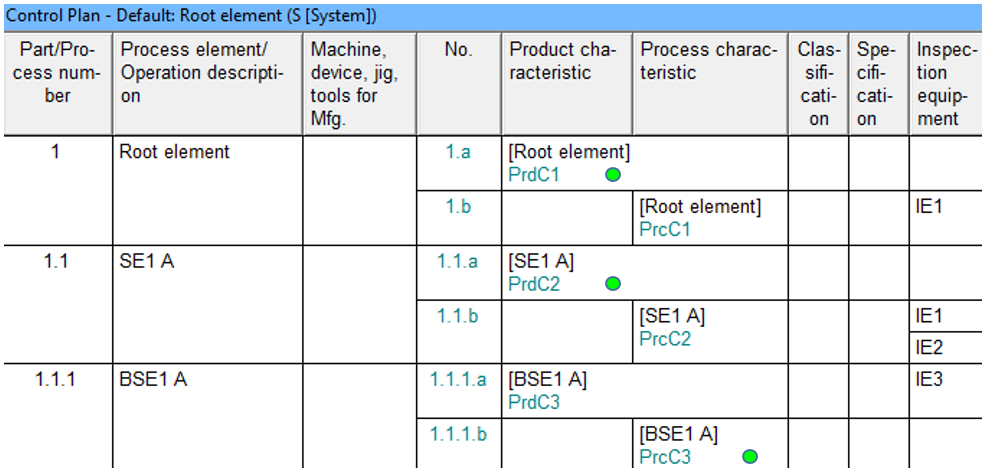

- This Quality Rule will find any characteristics, for which no inspection equipment has been assigned. Inspection equipment can be assigned to product- and process characteristics in the Control Plan Editor. The following image shows the control plan for this example.

- The way this control plan example looks is down to two reasons; one: while the product- and process characteristics are linked the way they are, and two: the following setting is active: Document settings | Control Plan | General settings for control plan | Display of process characteristics “is based on characteristic/function net”.

Search result: ![]()

In this example, the following characteristics will be found: product characteristics PrdC1 and PrdC2 as well as process characteristic PrcC3, as these do not have inspection equipment assigned.